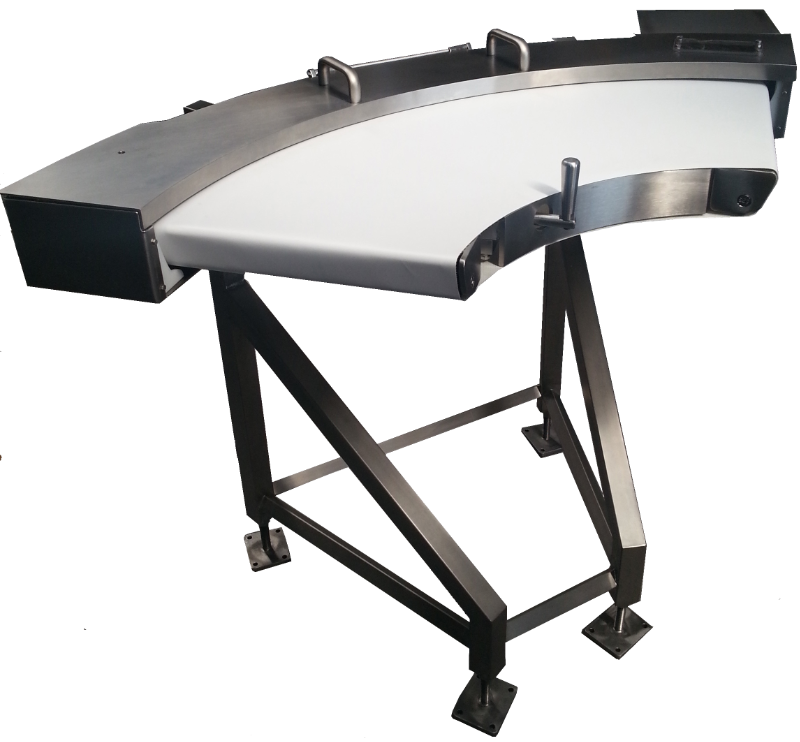

Hygenic Design Curves are LM’s curved conveyor system designed specifically to fulfil the needs of sectors where complete and total disinfection is crucial, as with fresh foods, dairy and some bread making applications. Initially developed as an optional upgrade of the cylindrical roller curves, the hygienic design curves have been in continuous evolution with the objective of facilitating washing and disinfection until it became an autonomous product with highly distinctive characteristics. They are characterised by a design that allows easy access to the inside and that guarantees reduced pooling surfaces, fewer hard-to-clean 90° corners and the elimination of contact surfaces. The construction mode allows, where possible, welding rather than assembly. The fundamental characteristics of LM curved belts remain, such as speed, compact dimensions and optimal control of the handled product.

Hygenic Design Curves

The LM hygienic cylindrical curves, the curved conveyor system for fresh foods, dairy and bread making, are suited for applications that require complete and total disinfection.

Hygenic Design Curves

Curves

Curves

- Maximum Weight of handled product 20 Kg/m

- Maximum Speed60 m/min

- Curving anglesFrom 30° to 180°

- End roller diameter60 mm, 16 mm

- Effective Width200 to 1200mm

- Internal Radius400 to 1200 mm

Suited for

Fresh food / Ready meals

Fresh food / Ready meals

Small/large trays, Dairy

Dairy

Unpackaged product (processed cheese, seasoned cheese, ), Bakery

Bakery

Unpackaged product (dry/coated/filled biscuits, Baked goods, Bread, Flat bread/wraps/pita bread, Crackers, Pizza, Savoury snacks/crisps, ), Confectionery

Confectionery

Unpackaged product (bars/snacks, soft/hard candies, pralines/chocolates, powder, ),