- Sorting Systems ,

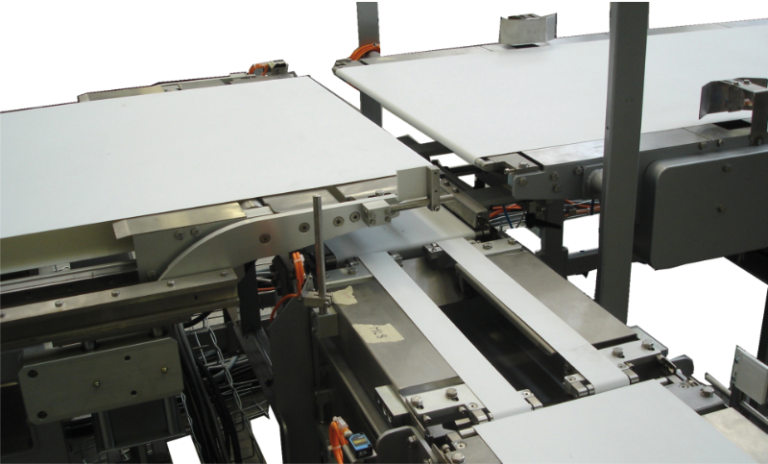

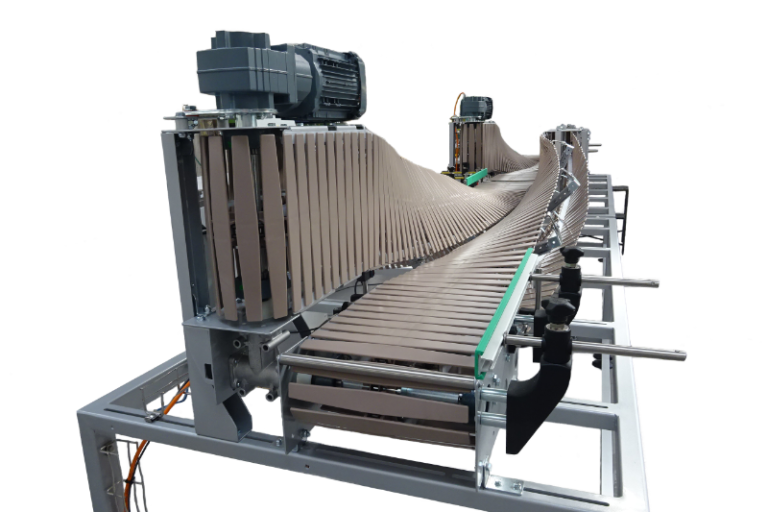

Conveyor system for primary packaging sorting, LM07 Multilaner guarantees high speeds thanks to the double movement of the swinging and telescopic guides, which perform the line change without slowing down or spacing out the product.